Florida DTF gangsheet troubleshooting begins with understanding how climate and setup shape results. From humidity in Florida to the quirks of your heat press, mastering the basics of DTF printing Florida helps you prevent color drift and misregistration. This guide highlights common DTF gangsheet issues and how to check DTF printer calibration to stay on target. By tuning heat press settings for DTF and aligning plates, shops can reduce DTF transfer problems and improve adhesion across batches. With a systematic approach, Florida-based shops can maintain consistent results even in challenging Florida conditions.

In other terms, this guide serves as a DTF sheet troubleshooting playbook, outlining the broader workflow for bulk designs. Emphasis on color management, film handling, curing, and transfer techniques helps address DTF transfer problems and build repeatable results. Consider the topic as a practical reference for optimizing the DTF process, including calibration, adhesion tuning, and environmental controls. Adopting an LSI-driven approach means using related concepts like print head maintenance, substrate compatibility, and quality assurance to support consistent output.

1) Florida-specific considerations for DTF printing and gangsheet layout

Florida shops face unique environmental factors that shape how DTF printing and gangsheet layout perform in real production. High humidity, warm temperatures, and variable air flow can affect adhesive behavior, curing times, and film handling. Planning layouts with these conditions in mind helps reduce misregistration and color drift, especially when multiple designs share a single gangsheet.

Understanding these Florida-specific variables enables better material selection and process timing. Tailor your gangsheet grid, margins, and gutter spacing to account for slight expansion or contraction during curing, and document any supplier-related differences in film or powder adhesives to minimize surprises across batches.

2) DTF printing 101: from design to transfer on gang sheets

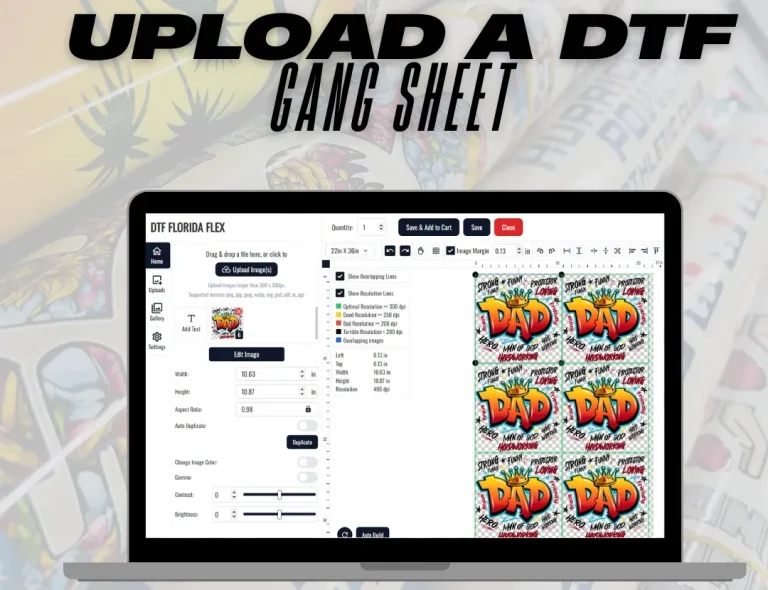

A gangsheet combines multiple designs onto one large sheet to maximize throughput and minimize setup time. In DTF printing, designs are laid out on transfer film, dusted with adhesive powder, cured, and then transferred to fabric with heat and pressure. Clear layout planning and accurate calibration reduce the risk of cascading misalignments across panels.

In Florida, environmental control during design and print stages helps preserve ink consistency and powder adhesion. Use consistent RIP settings, verify panel spacing, and run test panels to confirm that the transfer process remains stable across the entire gangsheet before committing to production.

3) Misalignment fixes for reliable DTF gangsheet transfers

Registration issues are one of the most visible DTF gangsheet problems. Misalignment between panels can ruin an entire run, especially when multiple designs share a single sheet. Begin with an accurate printer alignment check and a thorough nozzle check to ensure consistent ink deposition.

Next, verify the gangsheet layout in your RIP software, confirm margin consistency, and inspect platen guides for any wobble. Calibrate the feed path and replace worn components if necessary. These steps reduce cumulative misalignment and improve overall transfer accuracy.

4) Color fidelity in Florida: RIP calibration and color management

Color drift and dull prints undermine the value of DTF transfers. Effective RIP calibration and color management help you reproduce vibrant designs on diverse fabrics. Create or update ICC profiles tailored to your substrate and adhesive, and ensure the active color space matches your workflow.

Control ink density and print order to prevent muddy or oversaturated results. Validate with color test strips and reference swatches, adjusting profiles as needed. Proper film/adhesive compatibility also supports more accurate color reproduction across Florida’s climate.

5) Heat press settings for DTF: tuning temperature and pressure

Correct heat press parameters are essential for durable transfers. In Florida’s heat, insufficient time or pressure can lead to poor adhesion, while excessive heat can distort designs. Align temperature, dwell time, and pressure with fabric type, adhesive formulation, and transfer film to achieve consistent results.

Experiment with small test runs to identify the optimal settings for common substrates, especially cotton blends and synthetics. Document the chosen parameters so that future jobs maintain the same outcomes and avoid repeat trials under Florida-specific conditions.

6) DTF printer calibration for consistent Florida production

Regular calibration ensures uniform color and registration across gangsheet runs. DTF printer calibration should cover nozzle health, color density, and alignment across the entire print area. Use routine maintenance to keep lines crisp and avoid panel-to-panel variation.

In humid Florida environments, monitor ink flow and drying behavior to prevent early curing or static effects. Keep firmware and drivers up to date, and track calibration results to spot drift before it compromises a run.

7) Reducing ghosting and halos in DTF transfers on light fabrics

Ghosting and halos are often caused by insufficient curing or pressure management. Ensure the film is dry and cured fully before pressing, and confirm there is no static buildup on the substrate that could shift the design during transfer.

Review transfer temperature and dwell time to minimize faint outlines. Humidity control and humidity-friendly handling can help reduce moisture-related ghosting, especially on lighter fabrics where outlines are more noticeable.

8) Powder adhesion, curing, and film selection for Florida shops

Powder adhesion is critical for clean transfer edges and consistent results. Apply powder evenly to the wet ink surface and bake or cure the powder adherent thoroughly, adjusting cure windows for Florida heat when needed.

Select powder and transfer film combinations that are compatible with your fabrics. Verifying film type and adhesive compatibility can prevent color dulling and uneven residue, ensuring a cleaner transfer after pressing.

9) Adhesion reliability and wash durability for Florida customers

Durable adhesion depends on substrate compatibility, adhesive formulation, and proper post-transfer curing. Some fabrics demand longer dwell times or alternative adhesives to achieve reliable adhesion across multiple wash cycles.

Plan a small test batch on fabrics with similar properties to your customer base to verify durability. Clear documentation of heat press settings, curing times, and washing guidelines helps replicate results reliably for Florida shops.

10) Florida DTF gangsheet troubleshooting: quick-start flow and SOP integration

A practical quick-start flow helps Florida-based shops address common issues quickly and maintain throughput. Start with environmental checks, confirm material compatibility, and perform a nozzle check and alignment if needed. These steps often resolve misregistration and color drift early in the run.

Next, validate gangsheet layout in the RIP, print a test strip to assess color accuracy and alignment, and inspect powder application and curing before transferring to fabric. Document results and update SOPs to ensure consistent, repeatable outcomes for future Florida DTF gangsheet troubleshooting sessions.

Frequently Asked Questions

What is Florida DTF gangsheet troubleshooting and how does it address misalignment issues on prints?

Florida DTF gangsheet troubleshooting is a structured approach to diagnose and fix misalignment and related issues on gang sheets in Florida shops. To address misalignment, verify printer alignment and run a nozzle check, confirm the gangsheet layout in the RIP (margins, gutters, and panel spacing), ensure platen and registration guides are clean and properly seated, and calibrate the feed path. This systematic method helps achieve consistent registration across all panels even in Florida’s climate.

How can I fix color drift in DTF printing Florida during gangsheet runs?

Color drift in DTF printing Florida often comes from color management or material mismatches. Calibrate RIP color management, create or update ICC profiles for your substrate and adhesive, ensure the correct color space (CMYK with a white layer if needed), adjust ink density and layer order, check film and powder adhesive compatibility, and run a color test strip to fine-tune profiles.

What causes ghosting or halos in a Florida DTF gangsheet troubleshooting workflow?

Ghosting can result from moisture, static, or insufficient cure time. Ensure the transfer film is dry and properly cured before pressing, store film in a dry environment to prevent moisture uptake, review press temperature and dwell time, and check for static buildup on the substrate. If needed, use a humidifier or anti-static measures to reduce ghosting.

Why are powder adhesion problems common in DTF gangsheet issues and how can I fix them?

Powder adhesion problems arise when powder does not bond well to wet ink or when curing is incomplete. Apply powder evenly and ensure it adheres to the surface before curing, extend cure time in hot climates, use the recommended curing temperature for your powder adhesive and verify film compatibility with your substrate, and allow the transfer sheet to cool properly after curing.

What heat press settings for DTF optimize adhesion on Florida fabrics during gangsheet transfers?

Start with manufacturer guidelines for your fabric and adhesive. A practical baseline is around 165°C (329°F) for 15 seconds with firm, even pressure, then adjust by ±5–10 seconds or ±5°C based on adhesion results and fabric type. Always conduct a test transfer on similar substrates before full production.

How do I perform DTF printer calibration as part of Florida DTF gangsheet troubleshooting?

Perform routine calibration: run a nozzle check, execute print head alignment, and do color calibration with test patterns. Ensure firmware and drivers are up to date, and verify that the RIP’s color mapping remains accurate. Document results and consider Florida-specific factors like humidity and temperature that can affect drift.

What are typical DTF transfer problems on gang sheets and how can I resolve them in Florida?

Common transfer problems include poor adhesion, color shifts, and uneven transfer. Resolve by confirming substrate compatibility with the adhesive, adjusting heat press temperature and duration, improving powder curing, and verifying the transfer film and adhesive combination. In Florida, account for higher humidity and heat by extending cure times and stabilizing the work environment.

How do humidity and temperature swings affect Florida DTF gangsheet troubleshooting?

Florida’s humidity and temperature shifts can impact film handling, ink drying, and curing. Stabilize the workspace climate, store materials in dry containers with desiccants, extend cure times on humid days, and schedule sensitive jobs for periods of stable temperature to reduce variability.

What steps improve registration alignment on DTF gang sheets in Florida DTF gangsheet troubleshooting?

Improve alignment by verifying printer alignment and nozzle checks, confirming gangsheet layout in the RIP, cleaning and seating platen guides, checking for feed path skew, and validating panel spacing and gutters. Run test gang sheets to verify consistent alignment across the entire sheet.

What quick-start flow should I follow for Florida DTF gangsheet troubleshooting?

Quick-start flow: check environmental conditions and material compatibility; perform a nozzle check and alignment if needed; validate gangsheet layout in the RIP; print a test strip to assess color and alignment; inspect powder application and curing; transfer to the target fabric and evaluate adhesion and wash durability; document results and update your SOPs for future runs.

| Topic | Key Points |

|---|---|

| Introduction |

|

| What is a DTF gangsheet? |

|

| Why Florida-specific factors matter |

|

| Common problems and fixes |

|

| Workflow best practices for reliable Florida DTF gangsheet troubleshooting |

|

| Practical tips for Florida shops |

|

| Quick-start troubleshooting flow |

|

Summary

Florida DTF gangsheet troubleshooting is a disciplined approach to diagnosing and resolving print quality issues in Florida shops. By controlling alignment, color management, adhesion, and environmental factors, shops can achieve reliable, durable results across runs. A documented workflow, careful material selection, and ongoing testing help maximize throughput while minimizing waste, even in Florida’s climate.